What Are the Common Causes of Car Engine Failure?

Ricardo Fullwood • February 19, 2025

What Are the Common Causes of Car Engine Failure?

Ricardo Fullwood • February 19, 2025

Common Causes of Car Engine Failure

Car engine failure can be a frustrating and expensive issue for any vehicle owner. Whether due to neglect, mechanical wear and tear, or unforeseen circumstances, understanding the Causes of Car Engine Failure

can help prevent major breakdowns. Regular maintenance and timely inspections can save you from costly repairs, and seeking Engine Repair in Newark, DE can ensure your vehicle remains in optimal condition. This article explores the common reasons why engines fail and how to avoid them.

1. Lack of Regular Maintenance

Neglecting routine maintenance is one of the primary reasons engines fail. Regular servicing ensures that all engine components are working properly and that fluids are at optimal levels.

Key Maintenance Neglect Issues:

Skipping oil changes leads to sludge buildup and poor lubrication.

Neglecting coolant replacement results in overheating.

Worn-out belts and hoses can cause engine failure if not replaced on time.

Ignoring air and fuel filter changes reduces engine efficiency and increases wear.

Sticking to your manufacturer’s recommended maintenance schedule is the best way to avoid costly engine damage.

2. Overheating

An overheating engine is a common cause of failure and is often due to cooling system issues. Without proper cooling, engine components expand and warp, leading to severe damage.

Common Causes of Overheating:

Low coolant levels due to leaks.

Malfunctioning thermostat preventing proper coolant flow.

Radiator blockages restrict heat dissipation.

Faulty water pumps lead to poor circulation.

Regularly checking and maintaining your cooling system can help prevent overheating and engine damage.

3. Oil-Related Problems

Oil plays a crucial role in keeping an engine running smoothly. Without proper lubrication, moving parts generate excessive friction, leading to wear and failure.

Oil Issues That Cause Engine Failure:

Running the engine with low oil levels.

Using the wrong type or grade of oil.

Contaminated or old oil leads to sludge buildup.

Oil leaks causing insufficient lubrication.

Checking and changing oil regularly can prevent serious engine issues and prolong the life of your vehicle.

4. Timing Belt or Chain Failure

A timing belt or chain synchronizes the engine’s camshaft and crankshaft. If it fails, the engine can suffer catastrophic damage.

Signs of a Failing Timing Belt or Chain:

Ticking noise from the engine.

Misfiring or rough idling.

Difficulty starting the engine.

Visible wear or cracks on the belt.

Most manufacturers recommend replacing timing belts every 60,000–100,000 miles to prevent sudden failure.

5. Fuel System Malfunctions

A faulty fuel system can prevent an engine from receiving the necessary fuel to operate efficiently, causing poor performance or failure.

Common Fuel System Issues:

Clogged fuel injectors restrict fuel flow.

A failing fuel pump not delivering enough fuel.

Contaminated or bad fuel causes deposits in the engine.

Faulty sensors send incorrect fuel mixture signals.

Regularly replacing fuel filters and using high-quality fuel can help prevent fuel system-related engine issues.

6. Ignition System Failure

The ignition system starts the engine and ensures proper combustion. If it fails, the engine may stall or not start at all.

Common Ignition System Issues:

Worn-out spark plugs causing misfires.

Faulty ignition coils lead to weak sparks.

Damaged ignition wires disrupt the electrical flow.

Malfunctioning engine control module (ECM) affecting ignition timing.

Routine inspections and timely replacements can keep the ignition system functioning correctly.

7. Air Intake and Exhaust Problems

A car’s air intake and exhaust systems must function properly to maintain fuel efficiency and performance.

Air and Exhaust Issues Leading to Engine Failure:

Clogged air filters reduce airflow.

Blocked catalytic converters increasing backpressure.

Damaged oxygen sensors affecting fuel-air mixture.

Exhaust leaks lead to performance problems.

Replacing air filters regularly and monitoring exhaust system health can prevent these issues.

8. Electrical and Sensor Failures

Modern vehicles rely on a network of sensors and electrical components to regulate engine performance. A malfunction in these systems can lead to breakdowns.

Common Electrical and Sensor Issues:

Faulty mass airflow sensor affecting air-fuel balance.

Damaged crankshaft or camshaft sensors disrupt engine timing.

Battery or alternator failure causing electrical malfunctions.

Corroded wiring leads to intermittent engine issues.

Routine diagnostics can help detect sensor and electrical problems before they cause major damage.

9. Driving Habits and Engine Stress

The way you drive can also impact engine longevity. Aggressive driving and improper operation contribute to wear and tear.

Harmful Driving Habits:

Revving the engine excessively.

Frequently driving at high speeds.

Riding the clutch or improper gear shifting in manual transmissions.

Ignoring warning lights and continuing to drive with issues.

Practicing smoother and more mindful driving techniques can extend the life of your engine.

10. Contaminated or Poor-Quality Fuel

Using low-quality or contaminated fuel can clog fuel lines, damage injectors, and cause poor engine performance.

How to Avoid Fuel-Related Issues:

Purchase fuel from reputable stations.

Avoid driving with a low fuel level to prevent debris from entering the engine.

Use fuel additives to clean injectors and improve combustion.

Conclusion

Understanding the Causes of Car Engine Failure can help you take preventive measures to keep your vehicle running smoothly. Regular maintenance, timely part replacements, and addressing minor issues, before they escalate, can save you time and money. If you experience engine trouble, seeking professional Engine Repair in Newark, DE

ensures that your car is in expert hands. By being proactive and aware of these common issues, you can maintain a healthy engine and enjoy a reliable driving experience for years to come.

By Ricardo Fullwood

•

March 28, 2025

Auto brake fluid flush is a crucial maintenance service that ensures your vehicle’s braking system remains in optimal condition. Over time, brake fluid absorbs moisture and contaminants from the air, which can lead to decreased performance and even potential brake failure. The process of flushing brake fluid involves removing the old, degraded fluid from the brake system and replacing it with fresh, high-quality fluid. This helps to restore the system’s efficiency, safety, and responsiveness. Brake fluid plays a vital role in transferring the force from the brake pedal to the brake components. As moisture and contaminants build up in the fluid, they can cause corrosion in the brake lines and components, which reduces the overall lifespan of the braking system. Regular brake fluid flushes can prevent such issues and maintain the system’s performance. One of the primary advantages of a brake fluid flush is enhanced safety. By ensuring that the braking system functions effectively, you reduce the risk of brake failure in critical situations. Additionally, flushing the brake fluid can improve brake pedal response, giving you more control over the vehicle. It can also help avoid costly repairs down the road by preventing the damage caused by contaminated fluid. Regular brake fluid maintenance is an investment in both the safety and longevity of your vehicle. Understanding Brake Fluid and Its Role in the Brake System Brake fluid is a crucial component of a vehicle’s braking system. It ensures the proper functioning of the hydraulic braking system, enabling the vehicle to stop safely. Below are key points to understand its importance: Hydraulic Function : Brake fluid transmits force from the brake pedal to the brake components (like the calipers and brake pads) through the hydraulic system. Pressure Transmission : It allows the driver to apply consistent pressure to the brakes, making it easier to slow down or stop the vehicle. Types of Brake Fluid : The most common types include DOT (Department of Transportation) fluid, which comes in various grades (DOT3, DOT4, DOT5), and non-DOT fluids, such as mineral oil. Moisture Absorption : Brake fluid is hygroscopic, meaning it absorbs moisture over time. This can lower the boiling point of the fluid, causing brake fade or failure under heavy braking. Fluid Maintenance : Regular checks and changes of brake fluid are essential for maintaining braking performance and preventing corrosion of internal components. Signs of Problems : Symptoms of low or contaminated brake fluid include soft or spongy brake pedals, reduced braking power, or unusual brake response. What Happens When Brake Fluid Degrades? When brake fluid degrades, it can significantly affect the performance and safety of a vehicle. Brake fluid plays a critical role in transmitting force from the brake pedal to the brake components. Over time, brake fluid can break down due to moisture, heat, and contamination. Here’s what happens when brake fluid degrades: Loss of Brake Effectiveness : Degraded fluid can lose its ability to transfer force effectively, resulting in reduced braking power. This can make the vehicle feel less responsive and increase stopping distances. Corrosion of Brake Components : Moisture absorption in the brake fluid can lead to rust and corrosion in the brake lines, calipers, and master cylinder, causing premature wear and potential failure of these parts. Increased Risk of Brake Fade : As brake fluid absorbs moisture, its boiling point decreases. This can cause the fluid to boil during heavy braking, leading to brake fade, where the brakes lose their ability to stop the vehicle effectively. Pedal Feel Changes : Degraded fluid can cause the brake pedal to feel spongy or soft, making it harder for the driver to judge brake engagement and pressure. Potential Brake Failure : In extreme cases, degraded brake fluid can cause complete brake failure if moisture or contaminants cause internal damage to the brake system. Regular brake fluid checks and replacements are essential to maintain vehicle safety. Signs That Your Brake Fluid Needs a Flush Brake fluid is essential for the proper functioning of your vehicle’s braking system. Over time, brake fluid can degrade, become contaminated, or lose its effectiveness. Here are some signs that your brake fluid may need a flush: Spongy or Soft Brake Pedal : If the brake pedal feels soft or spongy when pressed, it could indicate air or moisture in the brake fluid. This can happen if the fluid is old or contaminated. Poor Braking Performance : If your car takes longer to stop or requires more effort to apply brakes, the fluid may have lost its ability to properly transmit the pressure to the brakes. Brake Warning Light : Many vehicles have a brake system warning light on the dashboard. If this light illuminates, it might signal low or deteriorated brake fluid. Discolored Fluid : Fresh brake fluid is usually clear or light amber in color. If the fluid appears dark brown or black, it has likely absorbed moisture, which can affect braking performance. Unusual Noises : If you hear squealing, grinding, or unusual sounds when applying the brakes, it could be a sign of contaminated brake fluid or insufficient fluid levels. Regular brake fluid checks and maintenance are essential for safe driving and optimal brake performance. How To Choose Best Brake Fluid Flush Services in Newark, DE When looking for the best brake fluid flush services in Newark, DE , it's important to consider several factors to ensure quality and reliability. First, research reputable auto repair shops and read customer reviews on platforms like Google or Yelp. Positive feedback from previous clients can offer valuable insights into the service quality. Next, inquire about the experience and certifications of the technicians performing the brake fluid flush. Certified mechanics are more likely to provide expert service, using the right tools and techniques to maintain your vehicle’s braking system. Check if the service includes a full inspection of your brake system. A reputable shop will not only flush the brake fluid but also inspect other brake components for wear and tear. This comprehensive service can help prevent costly repairs in the future. Also, compare pricing between different shops in Newark, DE, but avoid choosing solely based on cost. The cheapest option may not always provide the best value, especially if it compromises on quality or service standards. Lastly, ensure that the shop uses high-quality brake fluid that meets your vehicle's specifications. Using the right type of fluid is essential for maintaining brake system performance and safety. By keeping these factors in mind, you can choose the best brake fluid flush service for your vehicle. Conclusion: In conclusion, performing a brake fluid flush is a simple yet highly effective way to extend the life of your brakes and ensure the overall safety and performance of your vehicle. Brake fluid is essential for transmitting the force from the brake pedal to the brake components, but over time, it can become contaminated with moisture, dirt, and other debris. This contamination can reduce the fluid's effectiveness, leading to corrosion, diminished braking power, and potential brake failure. By flushing and replacing the brake fluid at regular intervals, you help maintain the fluid's integrity and prevent these issues from arising. Additionally, a brake fluid flush helps keep the brake system working optimally, improving the response time and reducing wear on the brake components. It also prevents excessive heat buildup, which can damage the brake system and lead to costly repairs. Regular maintenance, such as a brake fluid flush, is a small investment that can save you from more expensive fixes and ensure your braking system is always functioning at its best. Ultimately, a brake fluid flush is a key step in maximizing the longevity and reliability of your brake system, promoting safety, and enhancing your driving experience.

By Ricardo Fullwood

•

March 24, 2025

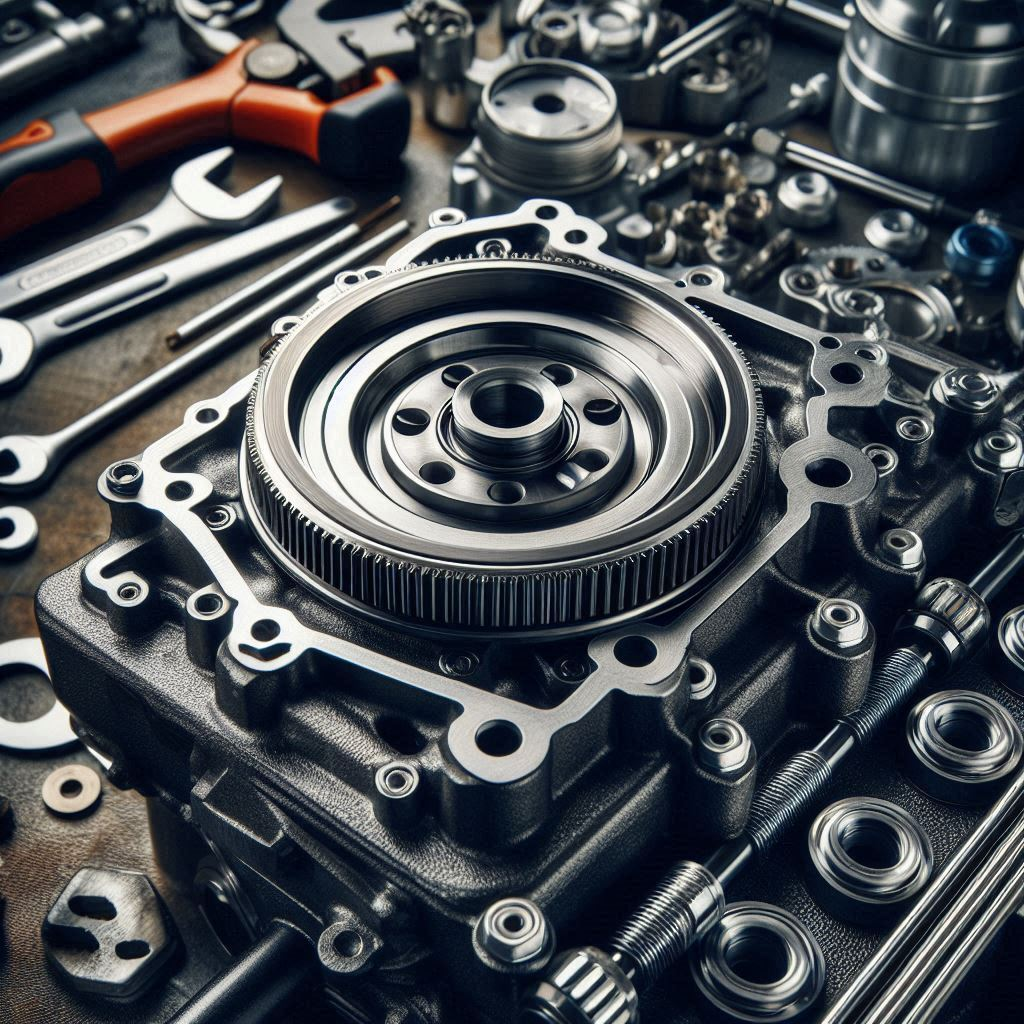

The head gasket is a crucial component in any internal combustion engine, playing a vital role in ensuring optimal engine performance. Positioned between the engine block and the cylinder head, the head gasket serves as a seal that prevents the leakage of coolant, oil, and combustion gases. Its primary function is to maintain the necessary compression within the cylinders while keeping the engine’s various fluids separate, ensuring that each part of the engine operates efficiently and without interference. A well-functioning head gasket ensures the engine runs smoothly, with proper compression and heat distribution. If the gasket fails, it can lead to a number of serious problems, such as coolant leaks, oil contamination, or loss of compression, which in turn can cause overheating, poor engine performance, and potential engine failure. The material and design of the gasket are carefully engineered to withstand the extreme temperatures and pressures of modern engines. In addition to preventing fluid leaks, the head gasket also plays a role in maintaining the overall longevity and efficiency of the engine. By ensuring the integrity of the engine's sealed environment, it helps preserve optimal fuel combustion, reduces emissions, and contributes to the engine’s overall reliability. Understanding the importance of the head gasket is essential for maintaining peak engine performance and preventing costly repairs. How the Head Gasket Works A head gasket is a crucial component in an internal combustion engine, serving as the seal between the engine block and the cylinder head. Its primary function is to maintain the proper compression within the engine's cylinders while preventing coolant and oil from mixing. By doing so, the head gasket ensures that the engine operates efficiently and safely. When the engine runs, the combustion process creates extremely high temperatures and pressures within the cylinders. The head gasket needs to withstand these forces while maintaining a tight seal between the engine components. This seal ensures that the gases produced during combustion remain within the cylinder, preventing leaks and loss of power. Additionally, the head gasket plays a critical role in managing the flow of coolant and oil through the engine. It prevents coolant from entering the cylinders and oil from leaking into the cooling system, which could lead to engine failure if mixed. Over time, head gaskets can wear out due to factors like overheating, engine vibration, or manufacturing defects. A blown head gasket can result in engine misfires, loss of power, or visible coolant/oil leaks. Regular engine maintenance, such as keeping the cooling system functioning properly, can help prolong the life of the head gasket and the engine overall. Impact of a Well-Functioning Head Gasket on Engine Performance A head gasket is a critical component in any internal combustion engine, sitting between the engine block and the cylinder head. Its primary role is to seal the combustion chambers, preventing coolant and oil from mixing, while also maintaining compression and controlling exhaust gases. A well-functioning head gasket has several positive impacts on engine performance: Efficient Sealing: A properly sealed head gasket ensures that combustion gases remain in the cylinders, boosting power and efficiency. Preventing Fluid Leaks: It stops coolant and engine oil from mixing, which can lead to engine damage or overheating if unchecked. Enhanced Engine Compression: The head gasket maintains the correct compression within the cylinders, optimizing fuel combustion for better power output. Prevents Overheating: By maintaining the seal, it helps prevent coolant loss, ensuring that the engine operates at the correct temperature, reducing the risk of overheating. Improved Fuel Efficiency: With proper sealing and efficient combustion, a good head gasket helps improve the overall fuel efficiency of the vehicle. Reduced Emissions: A well-functioning head gasket ensures minimal leakage of exhaust gases, leading to a cleaner engine and lower emissions. Longer Engine Lifespan: By preventing damage from coolant and oil mixing, a good head gasket helps extend the overall lifespan of the engine. Effects of a Failing Head Gasket A failing head gasket in a car engine can lead to severe and costly damage if not addressed promptly. The head gasket seals the engine block and cylinder head, preventing coolant and engine oil from mixing and ensuring the compression within the engine remains intact. When the gasket fails, it can result in various issues. One of the most common signs is overheating. A blown head gasket can allow coolant to leak into the engine, causing the engine to overheat and potentially warp or crack the cylinder head or engine block. Another consequence is the mixing of oil and coolant, leading to contamination that can damage critical engine components such as the pistons and bearings. Additionally, exhaust gases may enter the cooling system, creating air pockets and making it difficult for the radiator to maintain proper coolant flow. This can further exacerbate engine overheating. A damaged head gasket may also cause white smoke from the exhaust, as coolant burns off in the combustion chamber. In some cases, a blown head gasket can result in a loss of engine compression, leading to a decrease in power and performance. If the issue goes unresolved, it can eventually lead to a complete engine failure. Regular maintenance and early detection of head gasket issues are crucial to avoiding extensive repairs. How does a head gasket increase fuel efficiency? A head gasket plays a crucial role in improving fuel efficiency by ensuring proper engine performance. Here’s how it contributes to better fuel economy: Seals Combustion Chamber: The head gasket creates a tight seal between the engine block and the cylinder head, preventing leaks of combustion gases. By maintaining the integrity of the combustion chamber, it ensures optimal pressure during combustion, leading to more efficient fuel use. Prevents Coolant and Oil Leaks: The head gasket also prevents coolant and oil from mixing with the fuel or combustion gases. This helps maintain the correct engine temperature and reduces the likelihood of engine misfires or excessive fuel consumption due to poor lubrication. Maintains Compression: A properly sealed head gasket ensures that compression in the engine cylinders is consistent and within the ideal range. Higher compression improves engine efficiency, as more energy is extracted from the same amount of fuel. Optimizes Engine Temperature: By keeping the coolant contained and properly circulated, the head gasket contributes to better temperature regulation, which enhances fuel efficiency. An engine that runs at its optimal temperature burns fuel more efficiently. Reduces Engine Wear: By preventing internal leaks and ensuring smooth operation, a head gasket helps reduce friction and wear, which in turn lowers the engine's fuel consumption over time. In essence, a properly functioning head gasket is essential for achieving optimal fuel efficiency in an engine. How to Choose the Best Head Gasket Repair Service in Newark, DE When it comes to choosing the best Head Gasket Repair in Newark, DE , there are several factors to consider. The head gasket is a critical component of your engine, so selecting a reliable repair service is essential to ensure the longevity of your vehicle. Here are some key tips to help you make the right choice: Reputation and Reviews: Start by researching local repair shops in Newark, DE. Check online reviews, testimonials, and ratings on trusted websites like Google or Yelp. A service with positive feedback indicates trustworthiness and expertise in handling head gasket repairs. Experience and Expertise: Make sure the shop has technicians with experience in head gasket repairs. Look for certifications or years of experience in automotive repair to ensure they have the knowledge to address the issue accurately. Warranty and Guarantee: A good repair service should offer a warranty on their work. This shows confidence in their skills and provides you peace of mind knowing that you’re covered in case of future issues. Pricing Transparency: Obtain quotes from multiple shops in Newark, DE, and compare prices. Choose a service that offers fair and transparent pricing, ensuring that there are no hidden fees. By keeping these factors in mind, you can ensure a high-quality Head Gasket Repair in Newark, DE and keep your vehicle running smoothly. Conclusion: In conclusion, the head gasket plays a crucial role in maintaining optimal engine performance and efficiency. As a vital component situated between the engine block and cylinder head, it creates a seal that prevents coolant, oil, and combustion gases from mixing. This ensures proper compression within the engine, preventing leaks that could lead to reduced power, engine misfires, or even complete engine failure. The head gasket also aids in regulating temperature by ensuring the coolant flows properly through the engine, preventing overheating and contributing to the engine's overall longevity. When a head gasket fails, the consequences can be severe, including loss of engine power, increased fuel consumption, and costly repairs. Therefore, maintaining the integrity of the head gasket is essential for preserving the engine’s efficiency. Regular maintenance, timely inspections, and addressing any engine issues promptly can prevent premature head gasket failure and safeguard the vehicle’s performance. In summary, the head gasket’s role in sealing and temperature regulation is integral to the engine’s smooth operation, highlighting the importance of this often-overlooked component in ensuring both performance and efficiency in modern vehicles.

By Ricardo Fullwood

•

March 21, 2025

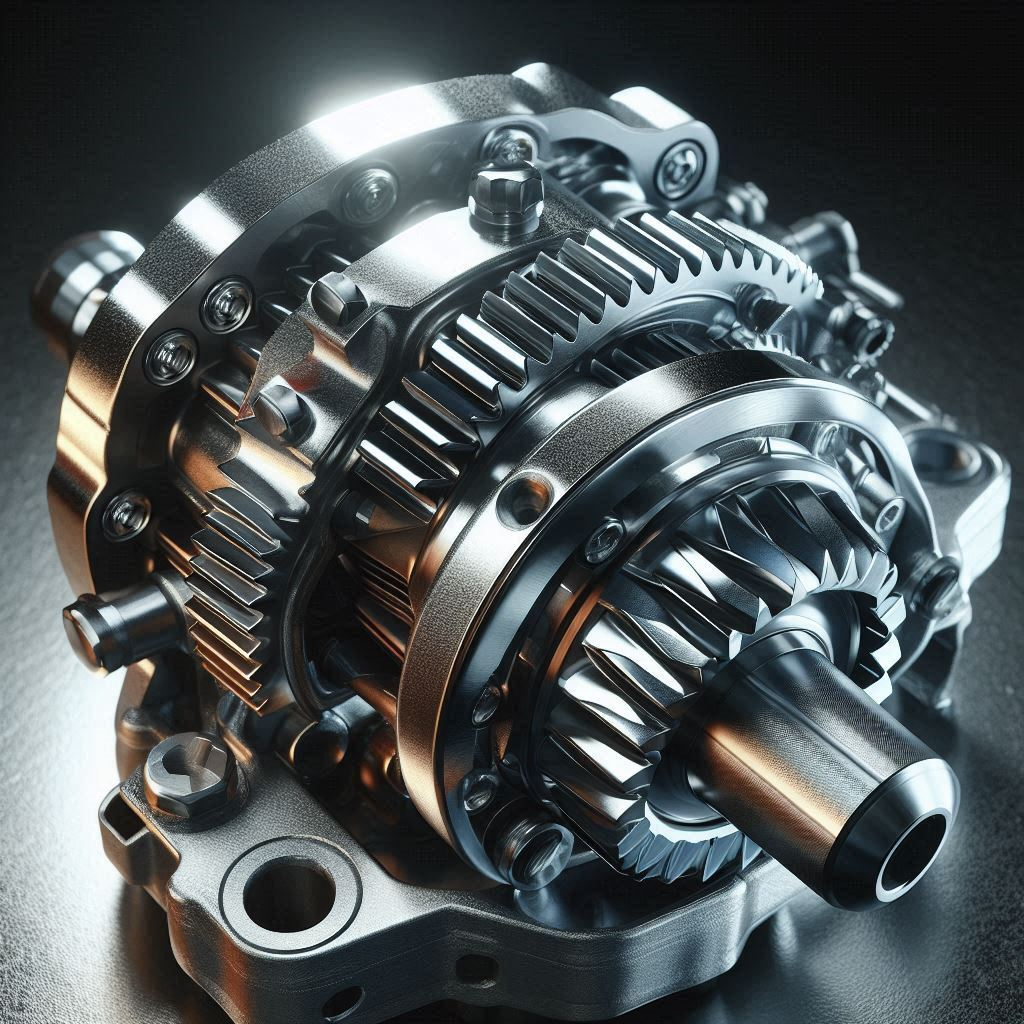

A car's differential is a critical component of its drivetrain, responsible for distributing power from the engine to the wheels while allowing them to rotate at different speeds. This is essential, especially when turning, as the inside wheels travel a shorter distance than the outside wheels. Without a differential, both wheels would be forced to rotate at the same speed, causing tire wear, handling issues, and potential drivetrain damage. The basic function of a differential is to allow each drive wheel to rotate independently, which provides the necessary traction and stability. It typically sits between the drive wheels (front or rear, depending on the vehicle) and contains gears that adjust the power sent to each wheel. This action helps prevent wheel slippage and ensures smoother turns. A differential also plays a significant role in your car's overall performance. A well-maintained differential improves handling, driving comfort, and efficiency, while an improperly functioning differential can lead to poor traction, uneven tire wear, and compromised acceleration. In high-performance or off-road vehicles, specialized differentials, such as limited-slip differentials, can further enhance handling and traction in various driving conditions. Understanding the importance of the differential can help drivers better appreciate its impact on both everyday driving and performance-oriented tasks. The Role of a Differential in Handling and Stability A differential is a crucial component in a car’s drivetrain, playing a significant role in handling and stability, especially when turning. It allows the wheels on the same axle to rotate at different speeds, which is essential when navigating curves or corners. When a vehicle turns, the inside wheel travels a shorter distance than the outside wheel. Without a differential, both wheels would be forced to rotate at the same speed, causing friction, tire wear, and a reduction in handling performance. In terms of handling, the differential ensures smooth and controlled turns, as it permits the outer wheel to rotate faster than the inner wheel. This reduces strain on the tires and suspension, enhancing grip and stability. A well-functioning differential also minimizes the likelihood of skidding or losing traction, especially on slippery surfaces like wet or icy roads. Moreover, the type of differential (open, limited-slip, or locking) impacts a car’s overall stability in various driving conditions. For example, a limited-slip differential provides better torque distribution between wheels, improving traction during acceleration and cornering, while a locking differential can be advantageous for off-road stability. Overall, the differential’s role is integral to ensuring that a car handles efficiently and maintains stability, providing both performance and safety. How the Differential Affects Traction and Grip The differential is a key component in a vehicle's drivetrain that helps manage the distribution of torque between the wheels, particularly during turns. It plays a significant role in maintaining traction and grip, ensuring the car handles efficiently. Torque Distribution: The differential allows the wheels to rotate at different speeds, which is essential during cornering. The inside wheel travels a shorter distance than the outside wheel, and the differential accommodates this difference, ensuring the wheels maintain proper traction. Improved Cornering: By compensating for speed differences between the left and right wheels, the differential helps the car navigate corners more smoothly, reducing the risk of sliding or losing grip. Traction Control: In vehicles with limited-slip differentials (LSD), power is more evenly distributed to the wheels, preventing one wheel from spinning too fast. This is especially beneficial in low-traction conditions (e.g., snow, mud), ensuring better grip. Handling Stability: A well-functioning differential contributes to overall stability. If the differential malfunctions or is poorly calibrated, it can lead to uneven tire wear or loss of traction, making the vehicle harder to control. Impact on Performance: For high-performance cars, advanced differentials (e.g., torque vectoring) offer superior traction, allowing better acceleration and handling in various driving conditions. How a differential can impact engine workload and efficiency A differential plays a critical role in a vehicle’s drivetrain system, particularly when it comes to managing engine workload and efficiency. Its primary function is to allow the wheels on an axle to rotate at different speeds, which is essential when a vehicle turns. Without a differential, the wheels would be forced to rotate at the same speed, causing tire wear and mechanical strain, especially during turns where the inside wheel travels a shorter distance than the outside wheel. By enabling the wheels to rotate at different speeds, the differential reduces the strain on the engine and other drivetrain components. This reduces the overall workload on the engine, preventing unnecessary power loss and heat generation. In turn, the engine can operate more efficiently, maintaining optimal fuel consumption and performance. Without an efficient differential, the engine would be forced to work harder to compensate for the uneven rotation of the wheels. This could lead to increased fuel consumption, overheating, and excessive wear on the drivetrain. In contrast, a properly functioning differential ensures smooth vehicle handling, reduces engine workload, and enhances overall efficiency by allowing the power generated by the engine to be better distributed across the wheels. Importance of maintaining the differential for long-term performance The differential in a vehicle plays a crucial role in ensuring smooth and efficient operation. Proper maintenance of the differential is key to preserving long-term performance. Here are some reasons why it's essential to keep the differential in optimal condition: Ensures Smooth Power Transfer The differential evenly distributes engine power to the wheels. Regular maintenance ensures smooth rotation and power distribution, preventing jerky movements that can damage the vehicle. Prevents Wear and Tear Neglecting differential maintenance can lead to excessive wear on gears and bearings. Over time, this can cause costly repairs or complete failure, impacting vehicle performance and safety. Enhances Fuel Efficiency A well-maintained differential ensures proper wheel synchronization, reducing unnecessary friction. This helps optimize fuel efficiency, leading to cost savings over time. Improves Handling and Stability The differential allows wheels to rotate at different speeds, especially during turns. Proper maintenance ensures the vehicle’s handling remains stable, improving safety, particularly in challenging driving conditions. Reduces Operating Costs By maintaining the differential, you reduce the likelihood of expensive repairs or replacements, ultimately lowering your vehicle’s overall operating costs. Regular checks and fluid replacements are key to maximizing the lifespan and performance of the differential. How to Choose the Best Differential Repair Service in Newark, DE Choosing the best differential repair service in Newark, DE , requires careful consideration to ensure you receive high-quality service at a fair price. Here are some key steps to guide you through the process: Research Local Options: Start by researching repair shops in Newark, DE. Look for ones that specialize in differential repairs and have positive customer reviews. Check Google, Yelp, and the shop's website for customer feedback and ratings. Certifications and Expertise: Ensure the service center employs certified technicians with experience in differential repairs. The best shops will have certifications from recognized organizations, indicating a high level of expertise. Get Recommendations: Ask friends, family, or local online communities for recommendations. Personal referrals can provide valuable insights into the reliability and quality of the repair service. Ask for Estimates: Contact a few shops and request estimates for the differential repair. A reputable shop will provide an upfront estimate based on the problem and the vehicle type. Be cautious of unusually low or high quotes. Warranty and Guarantee: A trustworthy repair shop will offer a warranty on parts and labor, giving you peace of mind that the repairs are backed by a guarantee. Conclusion: In conclusion, a differential plays a crucial role in enhancing a car's overall performance by ensuring optimal power delivery to the wheels, especially when turning or navigating uneven surfaces. By allowing the left and right wheels to rotate at different speeds, a differential reduces tire wear, improves handling, and enhances traction. This is particularly important in vehicles that experience varying levels of resistance on each side, such as in tight turns or on slippery roads. Without a differential, vehicles would struggle with poor handling and excessive strain on the drivetrain. The type of differential—whether an open, limited-slip, or locking differential—can also influence a car's performance, especially in terms of cornering ability, stability, and off-road capabilities. For example, a limited-slip differential provides better torque distribution to both wheels, which is especially beneficial in high-performance or off-road situations. On the other hand, a locking differential offers maximum power to both wheels, ideal for tough, low-traction environments. Ultimately, the differential is an essential component that optimizes a vehicle's handling, stability, and safety, ensuring smoother driving experiences and better control, regardless of road conditions.

By Ricardo Fullwood

•

March 19, 2025

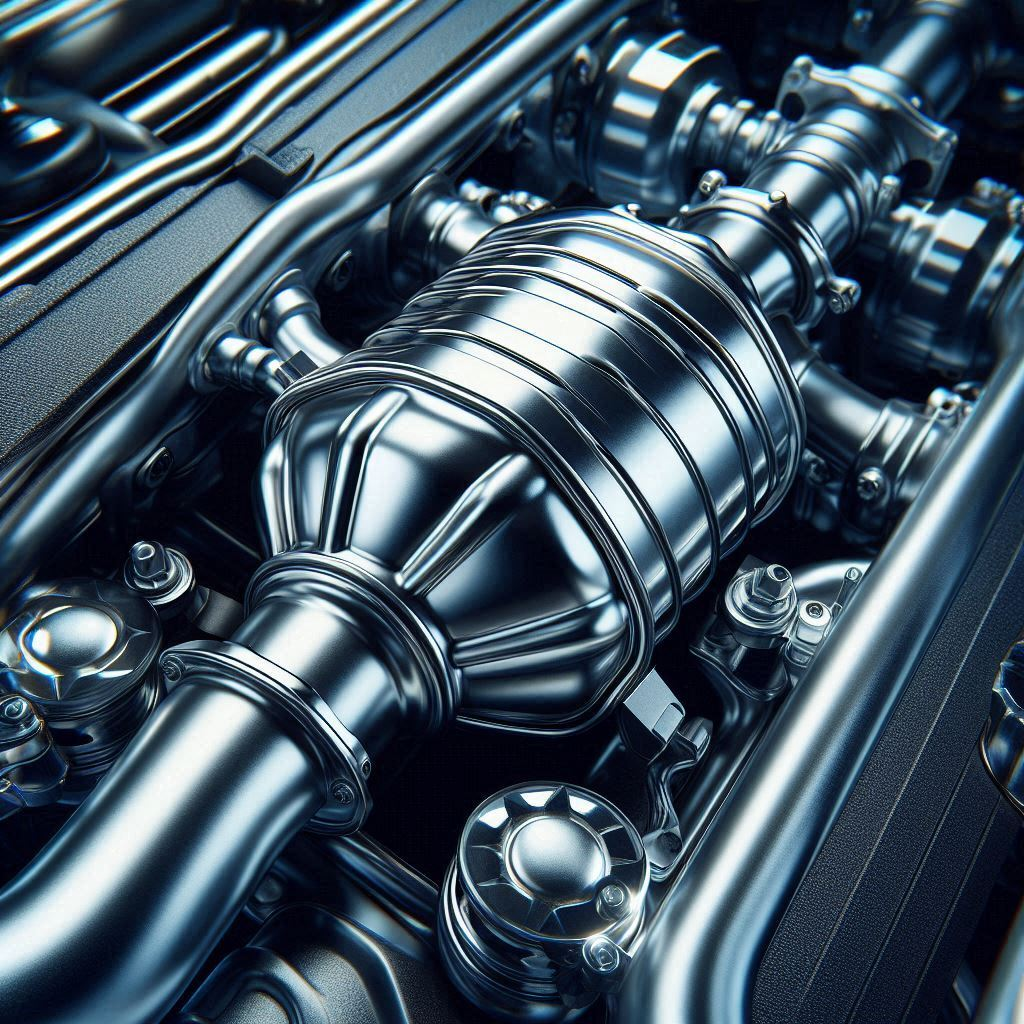

A catalytic converter is a critical component in modern vehicles, playing a vital role in reducing harmful emissions and ensuring compliance with environmental regulations. As cars produce exhaust gases during the combustion process, these gases can contain harmful pollutants like carbon monoxide, hydrocarbons, and nitrogen oxides. The catalytic converter, typically located between the engine and the muffler, helps convert these toxic substances into less harmful emissions before they exit the vehicle’s exhaust system. Working through a chemical reaction, the catalytic converter uses a combination of metals like platinum, palladium, and rhodium to facilitate the transformation of harmful gases into safer compounds, such as carbon dioxide and water vapor. By doing so, it helps reduce air pollution and contributes to improved air quality, making it an essential part of a vehicle's overall environmental impact. In addition to its environmental benefits, a properly functioning catalytic converter also improves a car's performance by optimizing the engine’s efficiency. However, when the catalytic converter fails, it can lead to increased emissions, reduced fuel efficiency, and even engine damage. This article will explore the importance and function of the catalytic converter in detail, highlighting its crucial role in both vehicle operation and environmental protection. How Does a Catalytic Converter Work? A catalytic converter is an essential component in a vehicle’s exhaust system designed to reduce harmful emissions. It works by converting toxic gases produced by the engine into less harmful substances before they are released into the environment. The catalytic converter contains a core made of a ceramic or metal substrate, which is coated with precious metals like platinum, palladium, and rhodium. These metals act as catalysts, which speed up the chemical reactions that neutralize harmful gases. When exhaust gases flow through the catalytic converter, they pass over the catalyst-coated surface. The three primary reactions that occur are: Reduction of Nitrogen Oxides (NOx): Nitrogen oxides, which contribute to smog and acid rain, are reduced into nitrogen (N2) and oxygen (O2). Oxidation of Carbon Monoxide (CO): Carbon monoxide, a poisonous gas, is converted into carbon dioxide (CO2). Oxidation of Unburned Hydrocarbons (HC): Hydrocarbons (such as unburned fuel) are converted into carbon dioxide and water vapor. By carrying out these reactions, the catalytic converter helps reduce the overall environmental impact of vehicle emissions, improving air quality and complying with emission regulations. How To Maintain Catalytic Converter ? Maintaining the catalytic converter in your car is crucial to ensure optimal performance and reduce harmful emissions. Here are some tips to keep your catalytic converter in good condition: Regular Engine Maintenance: Ensure your engine is running efficiently by performing regular maintenance, such as changing the oil and air filters and checking the spark plugs. A poorly running engine can cause excess fuel to enter the catalytic converter, leading to clogging or overheating. Avoid Short Trips: Frequent short trips prevent the catalytic converter from reaching its optimal temperature, reducing its efficiency. Long drives allow the converter to fully heat up and burn off contaminants. Monitor Fuel Quality: Always use high-quality fuel from trusted sources. Low-quality fuel or contaminated gasoline can damage the catalytic converter over time. Check for Leaks: Exhaust leaks can interfere with the catalytic converter’s function, leading to poor performance. Have the exhaust system regularly inspected for leaks. Address Engine Issues Promptly: If your engine’s performance begins to degrade (e.g., misfiring, poor acceleration, or increased fuel consumption), get it checked immediately. Delaying repairs can cause damage to the catalytic converter. Proper care will help maintain the catalytic converter, ensure better fuel efficiency, and contribute to a cleaner environment. How To Choose Best Catalytic Converter Replacement Service in Newark, DE When choosing the best catalytic converter replacement service in Newark, DE, there are several key factors to consider to ensure you're getting quality service and fair pricing. Reputation and Reviews: Look for a service provider with positive customer reviews. Websites like Google, Yelp, and BBB can give you insights into the experiences of others. Word-of-mouth recommendations from friends and family are also valuable. Experience and Expertise: Choose a shop that has experience working with catalytic converters. A team of skilled technicians will have the knowledge to diagnose the issue accurately and replace the converter properly. Certifications and Licensing: Ensure the shop is licensed and certified to perform emissions-related repairs. Certified technicians are trained in industry standards and can offer better quality service. Warranty: A reliable service provider should offer a warranty on both parts and labor. This ensures that if something goes wrong with the new catalytic converter, you won’t be stuck with additional repair costs. Pricing and Estimates: Get quotes from multiple shops to compare pricing. Be cautious of prices that seem too low, as they may be cutting corners on quality or using subpar parts. Customer Service: Good communication and transparency are crucial. Choose a service provider that is willing to explain the repair process and answer any questions you may have. Conclusion:

By Ricardo Fullwood

•

February 27, 2025

The automotive industry is experiencing rapid advancements, and one of the most critical areas of innovation is Car Suspension Technology . As vehicles become more sophisticated, the demand for better ride comfort, improved handling, and enhanced safety continues to grow. Whether you're driving through the busy streets of Newark, DE, or navigating rough terrain in Bear, DE, having a well-optimized auto suspension system can make all the difference. The future of auto suspension in Newark, DE, and auto suspension in Bear, DE, is set to change dramatically with the advent of smart systems, adaptive shock absorbers, and fully electric suspension setups. In this article, we will explore how Car Suspension Technology is evolving, from traditional setups to the latest cutting-edge innovations that promise to redefine the driving experience. The Evolution of Car Suspension Technology Suspension technology has come a long way from the basic leaf springs used in early automobiles to highly sophisticated electronic suspension systems in modern vehicles. Understanding how suspension systems have evolved over the years helps us appreciate the impact of today’s advancements. 1. Traditional Suspension Systems Leaf Springs and Coil Springs: Used in early vehicles, leaf springs were simple yet effective. Coil springs later replaced them for better flexibility and ride quality. Shock Absorbers: The introduction of hydraulic shock absorbers helped reduce vibrations and improved comfort. Independent Suspension: A major innovation allowing each wheel to move independently, leading to better handling and ride stability. 2. Introduction of Electronic and Air Suspensions With the rise of luxury and performance vehicles, electronic and air suspension systems became more common. These setups provide a smoother ride and adjust automatically based on driving conditions. Air Suspension: Uses air-filled bellows instead of coil springs, allowing for adjustable ride height and enhanced comfort. Magnetorheological Dampers: Found in sports cars and high-end sedans, these dampers use magnetic fluid to adjust suspension stiffness in real time. The Latest Innovations in Car Suspension Technology As we move into the future, several groundbreaking developments are set to revolutionize auto suspension in Newark, DE, and auto suspension in Bear, DE. Let’s take a closer look at the latest trends shaping the next generation of car suspension systems. 1. Adaptive and Active Suspension Systems Modern vehicles are increasingly equipped with adaptive suspension systems that use sensors to monitor road conditions and adjust shock absorbers accordingly. These systems provide optimal ride quality and handling. Active Dampers: Electronic control units adjust the stiffness of dampers in milliseconds, ensuring better stability on different terrains. Predictive Suspension Systems: Some high-end vehicles, such as Mercedes-Benz’s Magic Body Control, use cameras to scan the road ahead and prepare the suspension for upcoming bumps. 2. Fully Electric and Hydraulic Suspensions Electric suspensions are gaining traction, particularly in electric and autonomous vehicles. These systems replace traditional mechanical components with electronic actuators that provide precise control. Electromagnetic Suspension: Uses electromagnets to control wheel movement, offering a near-instantaneous response to road conditions. Hydraulic E-Active Body Control: A system that actively adjusts suspension height and stiffness for optimal comfort and safety. 3. Smart and AI-Integrated Suspension Systems Artificial intelligence (AI) is playing a major role in the evolution of Car Suspension Technology. By analyzing real-time data, AI-driven systems can optimize suspension settings for every driving scenario. Machine Learning Algorithms: Vehicles equipped with AI can "learn" from past driving conditions and automatically fine-tune the suspension for a smoother ride. Self-Healing Components: Future suspension systems may include materials that can repair themselves from minor damage, reducing maintenance costs. 4. Airless and 3D-Printed Suspension Components The automotive industry is experimenting with airless technology and 3D-printed materials to create more durable and efficient suspension components. Airless Suspension Systems: These suspensions use advanced polymers that mimic traditional shock absorption without requiring air or hydraulic fluids. 3D-Printed Shock Absorbers: Some manufacturers are using 3D printing to design lightweight yet strong suspension parts, reducing overall vehicle weight and improving fuel efficiency. Benefits of Advanced Car Suspension Technology The latest innovations in suspension technology offer several benefits to drivers and the overall automotive industry. Here are some key advantages: Enhanced Comfort: Smart and adaptive suspension systems adjust to road conditions in real time, providing a smoother ride. Improved Safety: Advanced suspension technology helps maintain better traction, reducing the risk of accidents. Fuel Efficiency: Lightweight and electronically controlled suspension components contribute to better fuel economy. Reduced Maintenance Costs: AI-powered diagnostics can predict suspension failures before they occur, preventing costly repairs. Better Handling: Sports cars and high-performance vehicles benefit from improved suspension control for enhanced driving dynamics. The Future of Auto Suspension in Newark, DE As technology continues to advance, drivers in Newark, DE, and Bear, DE, will soon have access to next-generation suspension systems that make driving safer, smoother, and more efficient. Many local auto shops and dealerships are already offering high-tech suspension upgrades to improve vehicle performance and comfort. What to Expect in the Coming Years Wider Availability of Smart Suspensions: Once limited to luxury cars, adaptive and AI-powered suspensions will become more affordable and available in mainstream vehicles. Integration with Autonomous Vehicles: As self-driving cars become more common, advanced suspension systems will play a key role in ensuring passenger comfort and safety. Eco-Friendly Materials: Automakers are exploring sustainable materials for suspension components, reducing the environmental impact of vehicle production. Conclusion The evolution of Car Suspension Technology is paving the way for a future where vehicles offer unmatched comfort, safety, and efficiency. From adaptive dampers and AI-integrated systems to electromagnetic suspensions and 3D-printed components, the automotive industry is constantly pushing the boundaries of innovation. For drivers in Newark, DE, and Bear, DE, staying up to date with the latest advancements in auto suspension can ensure a superior driving experience. Whether you’re looking for a smoother ride, better handling, or improved safety, upgrading to the latest suspension technology is a worthwhile investment. As these innovations continue to develop, it’s clear that the future of Car Suspension Technology will be defined by smarter, more responsive, and more efficient systems. If you're considering an upgrade, now is the perfect time to explore the latest advancements in auto suspension in Newark, DE, and auto suspension in Bear, DE .

Quality Service

You Can Trust.

Services

List of Services

-

Oil & LubeOil & Lube

-

Fluid FlushesFluid Flushes

-

Tire ServiceTire Service

-

Wheel AlignmentWheel Alignment

-

Tune-UpTune-Up

-

Air Conditioning RechargeAir Conditioning Recharge

-

Battery ReplacementBattery Replacement

-

Transmission MaintenanceTransmission Maintenance

-

Engine RepairEngine Repair

-

SuspensionSuspension

-

Exhaust WorkExhaust Work

-

DrivetrainDrivetrain

-

Engine ReplacementEngine Replacement

-

Transmission ReplacementTransmission Replacement

-

Catalytic Converter ReplacementCatalytic Converter Replacement

-

Differential RepairDifferential Repair

-

Car Water Pump ReplacementCar Water Pump Replacement

-

Car Timing JobCar Timing Job

-

Car Hub Bearing RepairCar Hub Bearing Repair

-

Head Gasket RepairHead Gasket Repair

-

Radiator FlushRadiator Flush

-

Brake Fluid FlushBrake Fluid Flush

List of Services

-

Oil & LubeOil & Lube

-

Fluid FlushesFluid Flushes

-

Tire ServiceTire Service

-

Wheel AlignmentWheel Alignment

-

Tune-UpTune-Up

-

Air Conditioning RechargeAir Conditioning Recharge

-

Battery ReplacementBattery Replacement

-

Transmission MaintenanceTransmission Maintenance

-

Engine RepairEngine Repair

-

SuspensionSuspension

-

Exhaust WorkExhaust Work

-

DrivetrainDrivetrain

-

Engine ReplacementEngine Replacement

-

Transmission ReplacementTransmission Replacement

-

Catalytic Converter ReplacementCatalytic Converter Replacement

-

Differential RepairDifferential Repair

-

Car Water Pump ReplacementCar Water Pump Replacement

-

Car Timing JobCar Timing Job

-

Car Hub Bearing RepairCar Hub Bearing Repair

-

Head Gasket RepairHead Gasket Repair

-

Radiator FlushRadiator Flush

-

Brake Fluid FlushBrake Fluid Flush